Spindle Drill

/The Southern Tier has a long history in the development and use of high precision machines to create the multitude of Printed Circuit Boards (PCBs) that are a key component in the manufacture of electronic equipment. In 2015, the Center for Technology and Innovation (CT&I) acquired a Sieb & Meyer CNC machine MD100 Spindle Drill from i3 Electronics that was in use through the 1980s. We have initiated a project to showcase the Spindle Drill technology and operation. The Spindle Drill will be the central component of an exhibit that will allow the visitor learn about the Spindle Drill technology by allowing the visitor to control the Spindle Drill.

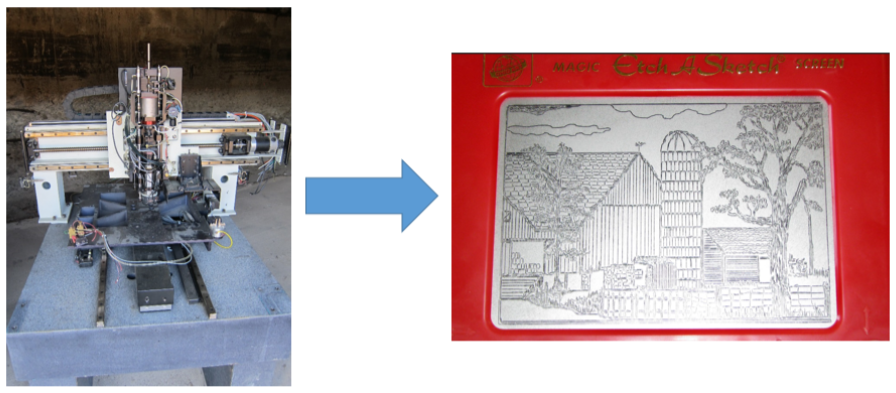

The Spindle Drill is designed to drill holes in PCBs in very precise locations under computer control. To highlight operation of the Spindle Drill, a series of projects is planned to allow a visitor to manually control the movement of the drill or have a computer-generated output based on input from the visitor. The first of a planned series of Spindle Drill projects is to allow the visitor to manually control the Spindle Drill with a custom-designed hand controller.

When CT&I acquired the Spindle Drill, it had been in storage for many years. Although storage was in a controlled environment, we did not know whether or how much of the equipment was operational. i3 Electronics engineers provided a valuable introduction and description of the equipment. However, there was not much detailed technical documentation available. In light of this, CT&I developed a two-year project that draws on the knowledge and skills of volunteers of CT&I, Triple Cities Makerspace, and senior Binghamton University (BU) students under the auspices of the Watson Capstone Project (WCP). The IEEE Binghamton Section has generously sponsored the Watson Capstone Senior Project.

For the 2015-2016 BU academic year, the WCP student team was charged with examining, documenting, and determining how much of the Spindle Drill could be made operational. The team successfully built a prototype hand controller that provided control of the Spindle Drill X and Y movement as well as limit switches.

For the 2016-2017 BU academic year, the WCP student team is charged with developing a hand controller suitable for visitors to use. The hand controller provides control of the Spindle Drill X-Y-Z movement and with a student-designed mounting bracket for a pen, an Etch-A-Sketch™ type exhibit will be created.

The Spindle Drill project is structured around the WCP curriculum. The WCP curriculum is designed to have the students work on a sponsored project that requires a student team with multiple skills to work with a set of defined requirements, schedules, and deliverables. The project is organized so that the WCP Team has major responsibility for the implementation of the requirements. CT&I provides the requirements and oversight. Both CT&I and Triple Cities Makerspace review the work of the WCP team and provide technical support through periodic meetings.